microdrop Technologies GmbH

Booth number: B03:41

www.microdrop-lifescience.de/

About us

microdrop technologies, with over 20 years of experience, specializes in microdispensing technology for handling and dosing technical liquids in pico- to nanoliter ranges. Our solutions cater to microtechnology, polymer electronics, and life sciences. We provide functional and feasibility solutions, working closely with customers on technically demanding challenges. Our highly automated products are used globally by industrial and high-tech companies, and R&D institutions. We offer a wide range of liquids for precise dispensing, whether single drops or high-speed printing. Based in Norderstedt, near Hamburg, we develop and sell products worldwide directly or together with our partners in China, Japan, and South Korea.

Address

Tycho-Brahe-Kehre 1, 22844 Norderstedt

22844 Norderstedt

Germany

E-mail: marc-manuel.hahn@microdrop.de

Phone: +49 40 5353830

Internet: www.microdrop-lifescience.de/

Contact person:

Products & Services

Microdrop provides precision dispensing systems in the pl and nl range, MD-E-5000 and Autodrop control units, plus full-service support from concept to installation.

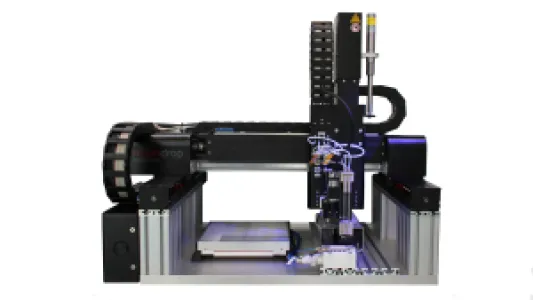

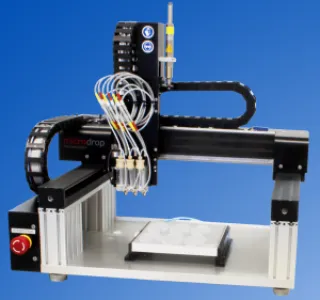

Autodrop Gantry

Need more than a microdispensing solution? We offer complete range of automated printing systems—from compact table-top systems for R&D and small-scale production to fully customized setups.

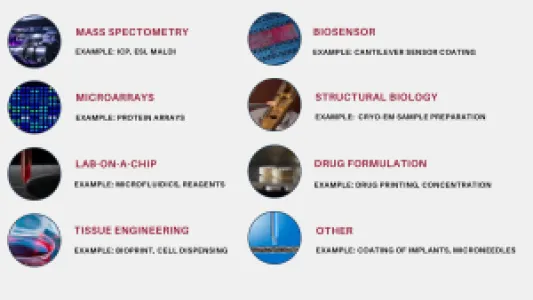

Our technologies support diverse fields: microlubrication, printed electronics, 3D printing, microarrays, and biosensor applications in life sciences.

Integratable Microdrop Dispensing System

MD-E-5000 Microdrop Dispensing System is a versatile, ready-to-use solution for high-performance microdispensing applications. Ideal for precise liquid handling in research, development, and production environments

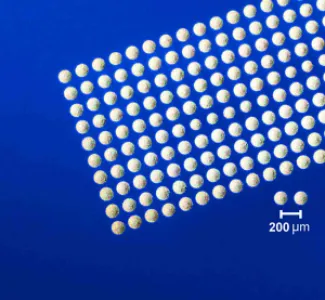

Autodrop Pipettes: Dispensing Aqueous Solutions in the Picoliter Range

Autodrop Pipettes from microdrop Technologies offer high-precision liquid handling based on advanced piezoelectric inkjet printing. Fluids are aspirated directly through the nozzle tip into a glass capillary, enabling rapid liquid exchange from multiple sources. A built-in piezo actuator generates a shock wave within the fluid, ejecting droplets with exceptional accuracy and consistency.

Key Features:

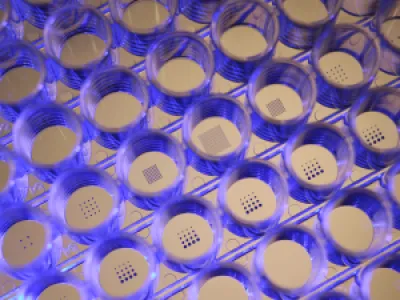

Drop-on-Demand Dispensing: Ideal for applications like biosensor or microarray production and high-throughput screening and spotting

Fast Liquid Change Enables: efficient aspiration from sources such as microtiter plates and supports automated cleaning.

Large Volume range available from up to 0.75 ml to 34 µl with minimal dead volume (~14 µl)

Glass Capillary Design: Enables automated cleaning and reduces cross-contamination risks

Compatible with both the MD-E-5000 dispensing system and automated workflows.

Autodrop Pipettes are engineered for demanding life science applications, including biosensor production, tissue engineering, and Lab-on-a-Chip system

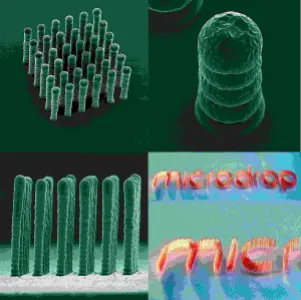

Microdrop Dispenser Heads for Printing Pico-Liter Drops of Various Materials

Microdrop Dispenser Heads are based on advanced piezo-driven inkjet printing technology. An integrated piezo actuator generates a shock wave within the fluid chamber, ejecting precise droplets from the nozzle — all without contact.

Key Features:

Drop-on-Demand Dispensing: Ideal for printing over larger areas with pinpoint accuracy

Large Reservoir: Handles fluid volumes up to 8 ml, enabling long walk-away times for automated workflows

Thermal Control: Heatable or coolable nozzle tips to accommodate a wide range of liquid viscosities

Rear-Loading Fluid Reservoir: Ensures clean and efficient dispensing

High Durability: Lifetimes exceeding 100 billion cycles

Compatible with both the MD-E-5000 dispensing system and automated workflows.

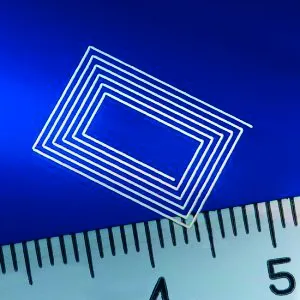

Nanojet Piezovalve- Nanoliter High-Precision Non-Contact Dispensing

microdrop’s Nanojet Piezovalves are engineered for ultra-precise, non-contact dispensing across a wide viscosity range — from low-viscosity fluids to hot melt adhesives (up to 2,000,000 mPas). These valves are ideal for applications in microelectronics, medical technology, and semiconductor manufacturing.

Key Features:

Piezoelectric Trigger Pulse: Ensures highly accurate droplet generation

Flexible Integration: Operates standalone or within Microdrop’s Autodrop Positioning System

Wide Volume Range: Models available for fluids from 5 nl to over 200 µl per cycle

Thermal Control: Operates between 10 °C and 50 °C

Robust & Stable: Designed for 24/7 industrial use

Modular Design: Easily exchangeable nozzles for different med

Services

Microdrop Technologies – Service Overview

microdrop offers specialized lab and engineering services to support complex microdispensing applications. These services ensure optimal performance by considering fluid properties, substrate interactions, and process demands from initial consultation to product installation.

Key Services:

Liquid Tests: Evaluate fluid compatibility, nozzle configuration, droplet dynamics, and dispensing parameters

Application Tests: Analyze substrate interaction, drying behavior, structure formation, and process optimization

Customer Training: Tailored sessions for production or R&D users to ensure smooth system integration

Strategic Partnerships: Collaborative development of new materials, processes, and products in fields like life sciences, microelectronics, and nanotechnology

With over 30 years of experience in inkjet and microfluidics, microdrop combines technical expertise with hands-on support to deliver reliable, high-precision dispensing solutions.